Off-Roading Suspension Basics: Understanding Suspension Systems and What Impacts Performance

Off-Roading Suspension Basics: Understanding Suspension Systems and What Impacts Performance

When it comes to off-roading, the suspension system plays a crucial role in ensuring both performance and comfort on rugged terrain. Understanding the basics of how off-road suspension works and the core components involved—such as shock absorbers, springs, and control arms—can help enthusiasts make informed decisions about upgrades. In this post, we’ll explore the key factors that impact off-road suspension performance, along with the benefits and potential drawbacks of different systems, helping you select the right setup for your needs.

Goal of Off-Road Suspension

The goal of off-road suspension systems is to enhance a vehicle’s performance and durability when navigating rough and uneven terrain. By allowing for greater wheel travel, off-road suspension helps maintain tire contact with the ground, improving traction and stability on challenging surfaces like rocks, mud, and sand, and by soaking up all the impacts that come from uneven terrain. This is important for off-road enthusiasts who require their vehicles to handle difficult conditions without compromising control or safety.

Off-road suspension systems are designed to absorb impacts and shocks that would otherwise be jarring for both the vehicle and the passengers, and improve component life in between maintenance intervals. Key components like shock absorbers and springs are engineered to distribute forces more evenly, protecting the vehicle’s chassis and ensuring a smoother ride. A properly tuned suspension system provides a balance between flexibility and control, optimizing the vehicle’s ability to traverse obstacles without damage, making it essential for serious off-road adventures.

How It Works

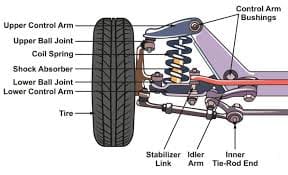

Off-road suspension systems work by allowing the vehicle’s wheels to move independently of the chassis, which helps maintain traction and control on uneven terrain. The suspension’s core components—shock absorbers, springs, and control arms—are designed to absorb the impact from obstacles like rocks or dips in the road, preventing damage to the vehicle and reducing the harshness felt by the passengers. The shocks dampen the movement of the springs, while control arms manage the positioning of the wheels, ensuring stability and smoothness.

The better the interaction between these components the better the off-road performance. Shock absorbers manage the energy produced by the springs, ensuring that the wheels remain grounded and reducing the chance of the vehicle losing control. Springs, whether coil or leaf, provide the flexibility necessary to handle rugged surfaces, while control arms, such as A-arms and 4-links, ensure the wheels move in a controlled manner. Together, these components create a system that balances flexibility, control, and durability.

What Are the Core Components and General Terminology?

The core components of off-road suspension include shock absorbers, springs, and control arms. Shock absorbers reduce the impact of bumps by controlling the compression and rebound of the springs, ensuring a smooth ride. Springs—either coil or leaf—provide flexibility to handle uneven terrain. Coil springs offer more precise control, while leaf springs are known for their durability in heavy-duty applications. Control arms, such as A-arms and 4-link systems, guide the movement of the wheels, maintaining proper alignment and ensuring stability during off-road maneuvers. These components work together to optimize suspension performance.

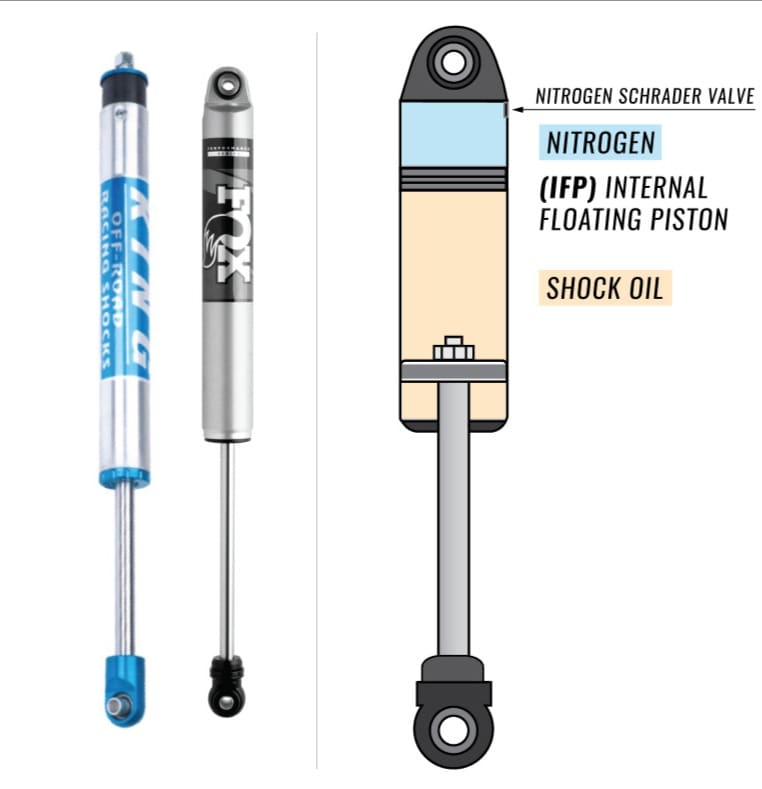

Shock Absorber

Shock absorbers are one of the best upgrades for your vehicle and come in a varity of performance levels. The goal of the shock is to manage compression and rebound of axle movement relative to the chasis. Shocks are typically broken down into the following types: emalsion, internal floating piston, and bypass. There are others out there, but these are the common types found in offroad capable vehicles (Jeep Wrangles and Ford Raptors for example) and the types of upgrades used to improve off-road performance.

Emulsion shocks are the cheapest and don’t provide much performance as the oil and nitrogen start to mix resulting in cavitation of the fluid which reduces dampening capabilities. The most common, and popular shock upgrade is to move to a shock that has a floating pistion which separates the oil from the nitrogen. This is important beacuse over time dampening remains predictable and consistent. Some sligth variations of the internal flaoting pistion design (or IFP for short) is the includion of a reserviour where the flaoting pistion resides. This allows for more shock travel in a smaller package which improves overall performance. Another variation of the IFP is to include compresson or rebound adjusters on the reserviour. This allows the user to increase or decrease dampening based on their unique needs, such as carrying additional weight. The top shock upgrade is to use a bypass shock. Bypasses are expensive, but provide the maximum level of performance. Bypass shocks work by allowing the user to have a much more resistive piston which translates to increased dampeneing, and use bypass ports/tubes to route some of the shock oil around the resistive pistion which results in the ride feeling softer in that specific zone. Most bypasses have 2-3 zones of compression and 1-3 zones of rebound, and are typically used on vehicles with a lot of wheel travel and additional other customiztion. Popular brands for off-road shock absorbers include Fox, King, and Bilstein.

Springs

Springs do more than just hold a vehile up, they provide the necessary flexibility to handle rough terrain. There are two primary types of springs: coil springs, which are known for their precise handling and control, and leaf springs, which offer durability and are ideal for heavier vehicles. Coil springs are used in conjunction with a 3, 4, or 5 link set up. The links connect the axle to the frame in a percise manor and the coils are usually located between the axle and the frame. Leaf springs are a much simpler suspension set up as there are less parts used to connect the axle to the frame. However, a coil spring suspension usually results in better flexibility and stability. Popular brands for off-road springs include Eibach, known for performance-focused coil springs, and Deaver leaf springs.

Control Arms

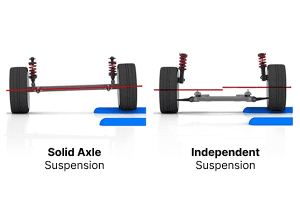

Control arms are responsible for managing the up-and-down motion of the wheels while keeping them aligned with the chassis. They provide better stability and control over rough terrain. A-arms are commonly found in independent suspension systems, offering precise movement for each wheel, while 4-link systems are typically used in solid axle setups, providing strong articulation for off-road environments.

A-Arms

A-arms (called A-arms because of the resembulance of the letter A) are used in independent suspension systems to allow each wheel to move independently, improving vehicle stability and control over rough terrain. This style of axle/suspension set up results in both an upper and lower A-arm connected to the spindle and the frame. A-arms are more limited in wheel travel vs. a solid axle with a 4 link set up. Most trophy trucks take advantage of the stability of an independant front suspension set up at a cost of wheel travel while leveraging much more wheel travel out of the rear as that is tyipcally a solid axle and 4 link set up.

4-Link

A 4-link suspension system is commonly used in solid axle setups, especially in off-road vehicles, to provide excellent articulation and improved axle control over rough terrain. This setup uses four control arms to link the axle to the vehicle’s frame, allowing for greater movement and stability while navigating obstacles. The 4-link system helps reduce axle wrap and offers better handling, particularly during climbs and descents. This approach also yields much more wheel travel, but at the expense of independant flexibility. However, wheel travel out of the rear can be as much as 12 or more inches when compared to the front for Trophy Trucks. The 4 link itself is a tried and true method for keeping the axle centered yet flexible in the rear. In most cases the lower links are connected from the frame to the axle in a straight line, and the top links are connected from the frame and meet at the center of the top of axle. Other common variations include the uppers or lowers starting in the center of the space between each frame side, and attaching toward the outter edges of the axle. A lot of new off-road vehicles today come with a slight variation to this approach, commonly referrred to as a 5 link set up. In this configuration both top and bottom links mount from the frame to the axle in a straight line, and there is a track or pan hard bar that is mounted from one side of the frame and goes diaglonally to the opposite side of the axle. These also typically use coil springs and provide a great ride for basic off-roading right off the factory floor.

What Factors Impact Performance the Most?

Several factors significantly impact the performance of off-road suspension systems. Wheel travel is one of the most crucial factors, as it determines how much vertical movement the wheels can make while remaining in contact with the ground. Increased wheel travel provides better traction on uneven terrain, improving the vehicle’s ability to traverse obstacles. A properly tuned suspension system with ample wheel travel helps to absorb shocks and prevent the wheels from losing contact with the ground and to maintain control on rough trails. Without sufficient wheel travel, the vehicle can become unstable, leading to reduced off-road performance.

Shocks and tires also play a key role in off-road suspension performance. Shocks control the movement of the springs, ensuring the suspension doesn’t bounce excessively and that the vehicle remains stable. High-quality shocks designed for off-roading provide better damping control and can handle the rough impacts associated with off-road driving. Tires, on the other hand, are the direct point of contact with the terrain. The right off-road tires, combined with an effective suspension system, improve grip and traction on loose surfaces like mud, sand, or rocks. Both shocks and tires must work in harmony with the suspension system to optimize the vehicle’s off-road performance.

Wheel Travel

Wheel Travel refers to the vertical distance the wheel moves as it encounters uneven terrain. It is critical for maintaining vehicle stability and ensuring tire contact with the ground. The more wheel travel a suspension allows, the better it can absorb road shocks and uneven terrain, leading to improved off-road capability. However, excessive wheel travel without proper balance can impact the vehicle’s ride quality and handling. Well-designed suspension components, such as coil springs and control arms, optimize wheel travel for optimal performance on rough trails.

Tires

Tires have a significant impact on a vehicle’s off-road performance as they are the primary point of contact between the vehicle and the terrain. The right off-road tires enhance tire contact with uneven surfaces, ensuring better grip and control. They work in tandem with the vehicle’s suspension system to absorb road shocks and maintain vehicle stability on rough terrain. However, improper tire selection can affect ride comfort, leading to a harsher experience and potentially causing uneven tire wear or reduced handling efficiency.

Summary

Off-road suspension systems are essential for enhancing performance on rugged terrain by maintaining vehicle stability, improving tire contact, and absorbing road shocks. Key components like shock absorbers, coil springs, and control arms work together to provide a smooth ride and optimize the vehicle’s ability to navigate obstacles while keeping wheels grounded. This results in better handling and overall performance.

However, upgrading off-road suspension systems also comes with drawbacks. Increased vehicle’s weight from added components can reduce payload and towing capacity, while the cost of premium parts like air suspension systems or suspension kits can be significant. Additionally, these upgrades may affect daily driving comfort, especially on highways.

Benefits – Performance Off-Road

Off-road suspension systems provide several benefits when it comes to off-road performance. These systems allow for better wheel travel, which ensures that the tires maintain contact with the ground, leading to improved traction and vehicle stability over rugged and uneven terrain. Components such as coil springs and shock absorbers help absorb road shocks, providing a smoother ride even on harsh trails. By optimizing suspension and ride height, these upgrades significantly enhance handling, allowing the vehicle to navigate difficult obstacles with greater control and confidence.

Drawbacks – Cost, Weight, and Daily Driving Capability (Payload and Towing Reduction)

While off-road suspension systems greatly improve off-road performance, they come with a few drawbacks. One of the main challenges is the increased vehicle weight, which can reduce the vehicle’s payload and towing capacity. Heavier suspension components, as needed to improve component/vehicle robustness on big obstacles, can make the vehicle less efficient for daily driving, particularly on highways. Additionally, the cost of high-performance parts and professional installation can be significant, making these upgrades a considerable investment for off-road enthusiasts.

FAQ’s

Here are five frequently asked questions about off-road suspension systems:

What are the key components of an off-road suspension system?

The key components of an off-road suspension system include shock absorbers, which control the movement of the springs and absorb impacts; springs, such as coil or leaf springs, which provide flexibility and handle weight distribution; and control arms, like A-arms or 4-link systems, which ensure the proper positioning and movement of the wheels. Additionally, components like sway bars and torsion bars may be used to enhance stability, while suspension kits or air suspension systems offer customization options for specific off-road needs.

How does wheel travel impact off-road performance?

Wheel travel significantly impacts off-road performance by allowing the vehicle’s wheels to move vertically over uneven terrain. Greater wheel travel ensures the tires maintain better contact with the ground, improving traction and stability when driving over rocks, mud, or other obstacles. This enhanced movement absorbs shocks more effectively, leading to a smoother ride and better handling. Without adequate wheel travel, vehicles may lose contact with the ground, reducing control and making it difficult to navigate challenging off-road environments.

What are the benefits of upgrading to a premium suspension system?

Upgrading to a premium suspension system offers several benefits for off-road performance. It enhances wheel travel, ensuring better traction and control over rugged terrain. Premium components like shock absorbers, coil springs, and control arms provide a smoother ride by absorbing road shocks more effectively, improving comfort and handling. Additionally, a high-quality suspension upgrade increases vehicle stability and helps prevent damage to the vehicle’s undercarriage during off-road driving. These upgrades also allow for better customization to meet specific performance needs.

How do off-road suspension upgrades affect daily driving comfort and towing capacity?

Depending on the upgrade and suspension tuning daily driving can feel more loose while seeing a reduction in fuel efficiency and tow/payload capacity, and this is more noticable with more advanced systems as the goal at that point is off-road performance.

What factors should I consider when choosing the right off-road suspension for my vehicle?

When choosing the right off-road suspension for your vehicle, consider several factors, including the type of terrain you plan to drive on, the performance goals you have, and your frequency of intended use. Evaluate the wheel travel, ride comfort, and vehicle stability you need for off-roading vs what the suspension kit is able to provide. Additionally, think about the vehicle’s weight and how the suspension upgrade might affect its payload and towing capacity. It’s also important to match the suspension system to your specific vehicle type, whether it’s a truck, SUV, or a more specialized off-road vehicle.